Precision measurements

Better design

Continuous flow Acoustic Separator

- The two phase acoustic separator consists of two precision bore tubes mounted vertically in a base connection block.

- One tube acts as a separation tube, where two immiscible fluids of different density separate due to gravitational forces. The second tube is the sensing tube where a meniscus between the two fluids is undisturbed by any flow in the separation tube.

- An acoustic transducer mounted in the base of the sensing tube measures fluid level.

- DCI uses longer precisely machined bores with smaller diameters to increase resolution. In this design a small change in volume creates a larger increase in reflection time thus giving better resolution and increased accuracy.

- The electronics for the two phase separator give the user the capability to adjust signal amplitude and trigger level making the most difficult to detect meniscuses easily visible.

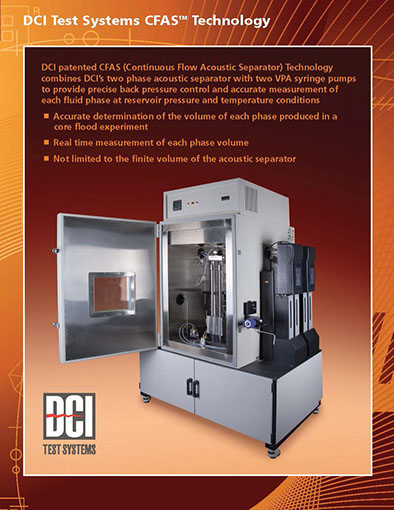

- Combining the Acoustic Separator with DCI’s VPA syringe pumps create DCI’s CFAS™ technology.

- CFAS™ technology creates an infinite volume two phase separator with back pressure control

- The VPA precisely measures fluid being produced, all while maintaining the user settable backpressure.

- CFAS™ technology is the ultimate resource for accurately measuring multi-phase flow from core samples.

Software

Software for the two phase separator is provided with every unit and displays the volume of the lower density fluid as well as graphical representation of fluid levels inside the cylinders. The acoustic separator software is easily integrated into more complex systems such as core flooding programs to keep track of produced fluids and saturation state.

Specifications

Features

Downloads

Gallery

| Acoustic Separator / Two Phase Separator Specification | |

|---|---|

| Separator Volume | 150 ml |

| Measurement Volume | 100 ml |

| Measurement Accuracy | 0.1 ml |

| Measurement Resolution | 0.01 ml |

| Anlong Ouput Range | 3.3 V DC |

| D/A Resolution | 16 bit |

| Wetted Material | Titainum |

| Max Pressure | 10,000 psi |

| Max Temperature | 150°C |

Precision Measurements

The two phase acoustic separator consists of two precision bore tubes mounted vertically in a base connection block. One tube acts as a separation tube, where two immiscible fluids of different density separate due to gravitational forces. The second tube is the sensing tube where a meniscus between the two fluids is undisturbed by any flow in the separation tube. The higher density fluid communicates between the two tubes in the base connection block. The lower density fluid communicates through a similar connection block mounted to the top of the two tubes. An acoustic transducer mounted in the base of the sensing tube uses the reflection time of acoustic waves reflected from the meniscus between the two fluids to measure the volume of the higher density fluid in the separator. Proprietary data reduction techniques provide high accuracy, high resolution data.

Better Design

DCI uses longer precisely machined bores with smaller diameters to increase resolution. In this design a small change in volume creates a larger increase in reflection time thus giving better resolution and increased accuracy. The electronics for the two phase separator give the user the capability to adjust signal amplitude and trigger level making the most difficult to detect meniscuses easily visible.

Continuous Flow Acoustic Separator Technology

DCI’s CFAS™ technology (Patented) incorporates the two phase separator with two VPA syringe pumps to provide highly accurate measurement of the volume of two different phases that are produced in a core flood experiment, even when the volumes of fluids produced exceeds the volume capacity of the two phase separator. In this arrangement, one of the VPAs is operated in external transducer feedback mode, with the analog signal from the two phase separator as the feedback signal. In this mode, the VPA receives any of the higher density fluid that is produced and maintains the meniscus level at a constant level in the separator. Thus, the VPA provides a very accurate measurement of the volume of the higher density fluid that is produced. The second VPA is connected to the upper outlet port of the two phase separator (outlet for the lower density fluid). This VPA operates in a pressure feedback mode, thus controlling the back pressure in the two phase separator, and on the sample in the core flood experiment. Any of the lower density fluid that is produced by the experiment is received by this second VPA, and the volume received is measured precisely. Using dual cylinder syringe pumps in each of these two functions provides the ability to receive infinite volume of either fluid that is produced by the system. This allows volumes of fluid larger than the capacity of the two phase separator to flow through the sample while equilibrium is established, and still maintain a precise measurement of each fluid volume that is produced.

Software

Software for the two phase separator is provided with every unit and displays the volume of the lower density fluid as well as graphical representation of fluid levels inside the cylinders. The acoustic separator software is easily integrated into more complex systems such as core flooding programs to keep track of produced fluids and saturation state.

Two Phase Acoustic Separator

CFAS™ (Continuous Flow Acoustic Separator Technology)

Acoustic Separator Software User Interface

Two Phase Acoustic Separator

©2022 DCI Test Systems

All Rights Reserved

Special Core Analysis

Routine Core Analysis

Rock Mechanics

Accessories

Fluid Properties

About DCI