Rock Compressibility Systems

Precise reservoir simulation for

accurate understanding of rock

and fluid flow behavior

Industry leader

Robust features for every testing need

Intuitive software

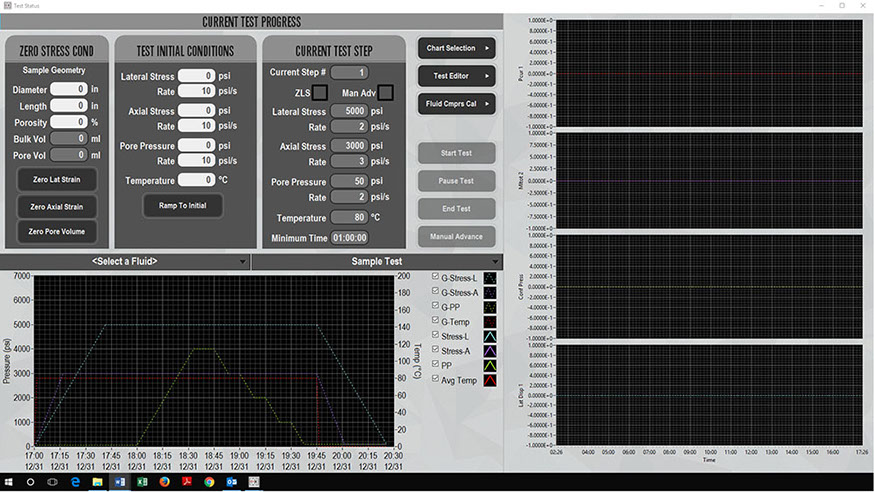

- Fully automatic control for lateral, axial, and pore pressures allows for the user to preprogram pressure profiles for draw down tests.

- Axial displacement and lateral displacement instrumentation to fully analyze the changes in bulk, pore, and grain volumes of the sample.

- “Zero lateral strain” uses the lateral displacement transducer as feedback for the lateral pressure syringe pump, allowing lateral strain to be held constant. This more accurately simulates reservoir conditions.

- Fully integrated software allows the user to easily setup and monitor tests

- Graphical plots show system parameters and pressure/strain profiles

- Step by step user interface makes running a test easy

- Records all data and channels to a tab separated text file which can be converted to Excel or other data reduction software formats.

Industry leading core holder design and components.

- All components are designed and machined by DCI for the best quality

- Hastelloy and SS options are available

- Easy to load hydrostatic and triaxial core holders available.

- Pressures provided by DCI’s accurate VPA syringe pumps

More configurability

We know that not all users need the same system, and the DCI rock compressibility system can be configured with the options that fit your testing requirements. Contact us so we can help you decide what features best fit your needs.

Specifications

Features

Gallery

| Example of a Rock Compressibility System Specification |

|

|---|---|

| (Many sample sizes and pressures available, contact us for specific details) | |

| Sample Dimensions | |

| Length: | 1"-3" |

| Diameter: | 1" & 1.5" |

| Rated Lateral Stress: | 15,000 psi |

| Rated Axial Stress: | 15,000 psi |

| Rated Pore Pressure: | 15,000 psi |

| Wetted Material: | Hastelloy or 316SS |

| Rated Temperature: | 150°C |

| Load Cell: | 20,000lbs / 1.0% FS |

| Axial Strain: | 15% Sample Length / 1.0% FS |

| Lateral Strain: | 10% Sample Diameter / 1.0% FS |

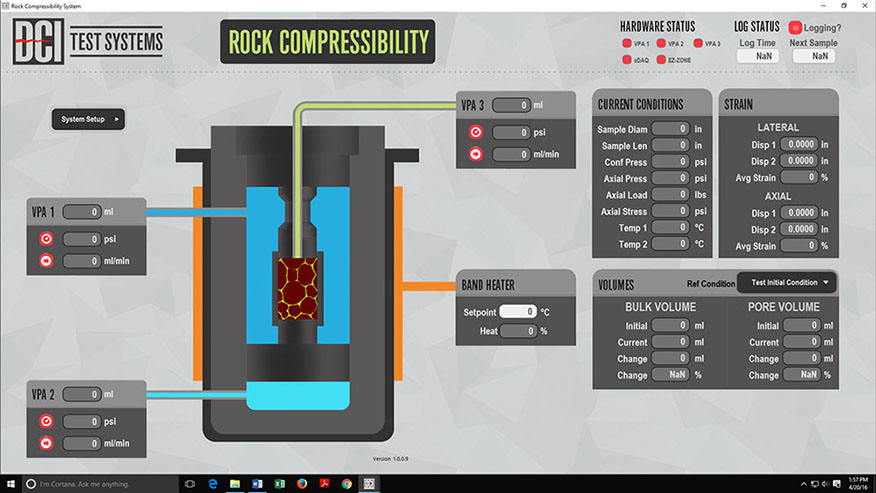

The rock compressibility system is made up of a number of components that are integrated into a single system. We know that not all users need the same system, and the DCI rock compressibility system can be configured with the options that fit your testing requirements. Each aspect of the equipment can be configured to meet your needs. These components include:

Core holders:

The core holders for these types of systems are generally triaxial type, but can also be hydrostatic or hassler. All core holders are designed to be compatible with in-vessel instrumentation.

Pore pressure control/pore volume measurement system

The heart of this system is DCI VPA syringe pumps. The VPA syringe pump utilizes an industry leading actuator servo motor to move the piston. The servo motor allows very precise control of the syringe pump piston. An encoder provides exact position feedback of the servo motor, allowing the volume of the fluid displaced or received by the syringe pump to be known very precisely (the encoder resolution for volume measurement is less than 1 nano liter). The VPA also provides precise pressure control of the pore pressure in the sample.

Lateral pressure control system

Pressure is typically provided by a VPA syringe pump. This allows automatic lateral pressure control. With automatic pressure control the software can be easily setup to run programed stress profiles. Feedback from lateral strain instrumentation is also measured by the VPA syringe pump giving it the ability to control pressure to meet a user settable lateral strain target. Other options for lateral pressure control are available, contact us for more details.

Axial (overburden) pressure control system

Pressure is typically provided by a VPA syringe pump. This allows automatic axial pressure control. VPA syringe pump measures and controls pressure based on feedback from an in-vessel load cell. This eliminates error from seal friction and other factors that may not give accurate axial load. Other options for axial pressure control are available, contact us for more details.

In-vessel sample instrumentation

In-vessel instrumentation includes lateral strain transducers, axial strain transducers and axial load cell. Each instrument is factory calibrated and designed for the most accurate measurements possible.

Heating Systems

Simulating reservoir conditions is important. Each system is equipped with a heating system that can be configured differently depending on options and testing needs. Contact us for more

Information.

Automated data acquisition and test control system

Software is the brain of the system and makes for easy setup and control. In software the users can setup a test, create test profiles and record data/view data.

Bulk Volume/Pore Volume Rock Compressibility System

Rock Compressibility System Sample Instrumentation

Rock Compressibility System Electronics

Rock Compressibility System Electronics2

Rock Compressibility System Electronics3

Rock Compressibility System User Interface Test Profile

Rock Compressibility System User Interface

©2022 DCI Test Systems

All Rights Reserved

Special Core Analysis

Routine Core Analysis

Rock Mechanics

Accessories

Fluid Properties

About DCI